A world-class asset,

a landmark investment

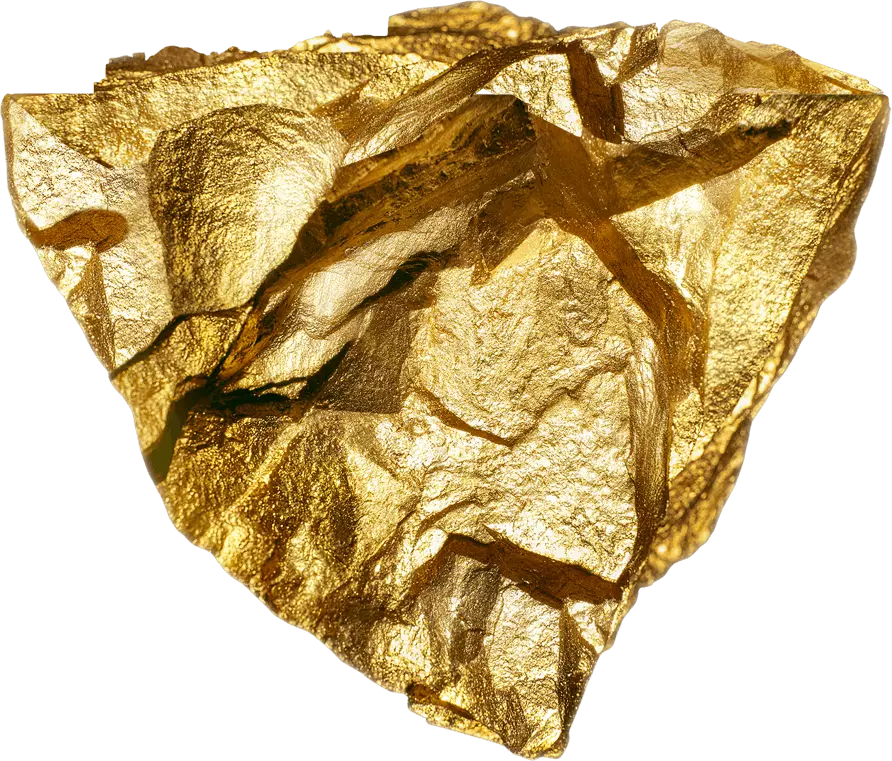

The Skouries project is part of the Kassandra Mines, located at the Halkidiki peninsula in northern Greece. This copper-gold porphyry deposit will be mined using a combination of conventional open pit and underground mining technologies, alongside the best-in-class sustainable practices. Based on the 2021 Feasibility Study, the initial life of the mine is approximately 20 years, and it is expected to produce on average 140,000 ounces of gold and 67 million pounds of copper per year.

Once operational, it will place Greece among the top three gold-producing countries in Europe. Greece will also become a significant producer of copper contributing to the transition of the EU to a circular economy.