Innovative technologies

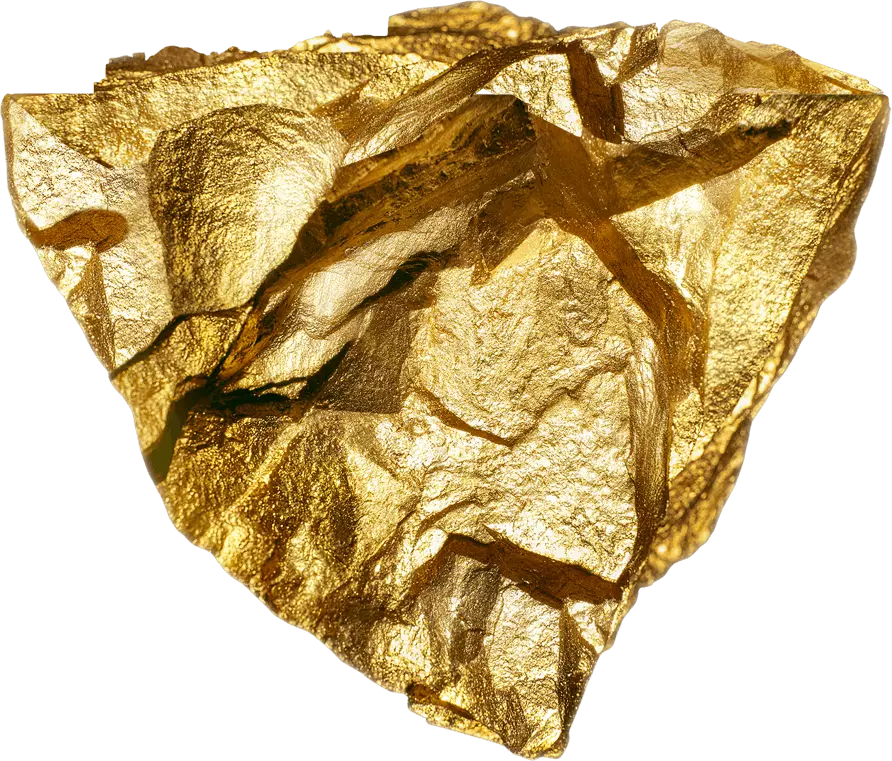

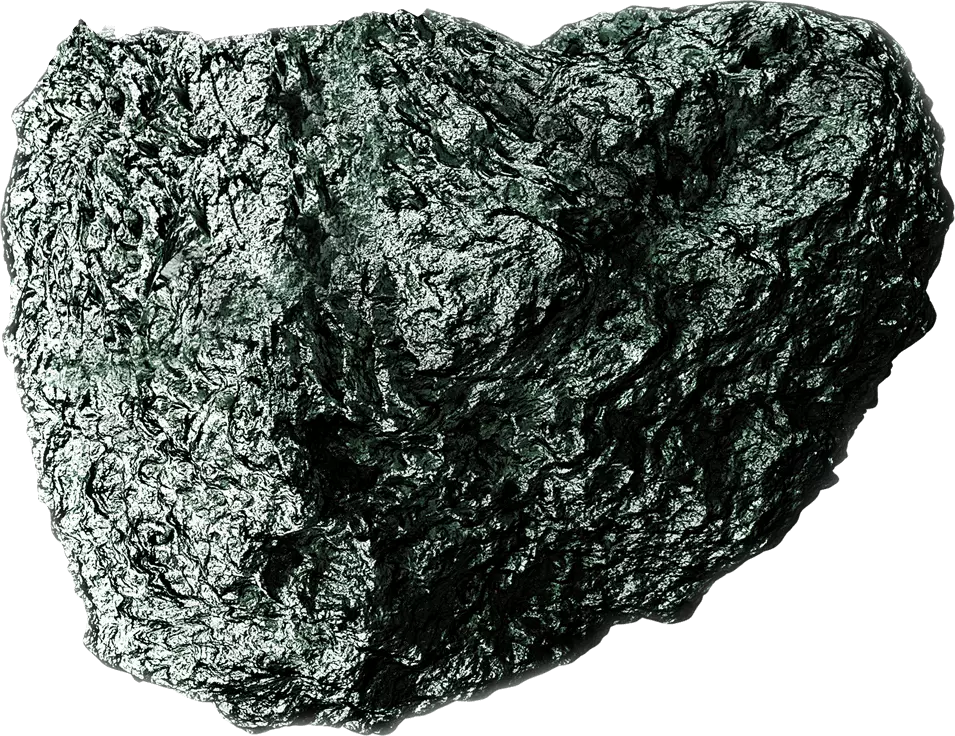

The gold, lead, silver and zinc underground mine in the state-of-the-art mining facilities at Olympias entered production in 2017. The mine's flotation plant produces three types of concentrates: gold, lead-silver and zinc, with an estimated life cycle of 15 years, based on current proven and probable reserves.